Comparison of different quality specifications followed in cashew trade:

Here is a comparison of the quality standards and specifications as followed and given by Cashew Export Promotion Council of India (CEPC), United Nations Economic Commission for Europe (UNECE), Brazilian cashew industry, Viet Namese cashew industry and Association of Food Industries (AFI, New York).

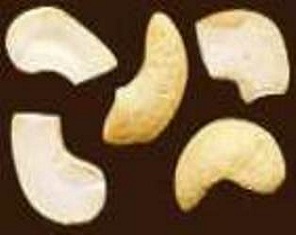

CASHEW KERNELS – WHITE WHOLES

|

|

White Wholes – 210 White Wholes – 210 |

White Wholes – 240 White Wholes – 240 |

White Wholes – 320 |

White Wholes – 450 White Wholes – 450 |

|

CASHEW KERNELS – SCORCHED WHOLES

Scorched Wholes SW |

Scorched Wholes SW – 180 |

Scorched Wholes SW – 210 |

Scorched Wholes SW – 240 |

Scorched Wholes SW – 320 Scorched Wholes SW – 320 |

Scorched Wholes SW – 450 |

Scorched Wholes SW – 500 |

CASHEW KERNELS – DESSERT WHOLES

|

|

|

CASHEW KERNELS – WHITE PIECES

|

|

Splits S Splits S |

Large White Pieces (LWP) Large White Pieces (LWP) |

Small White Pieces (SWP) Small White Pieces (SWP) |

Baby Bits BB |

|

CASHEW KERNELS – SCORCHED PIECES

|

|

Scorched Splits SS Scorched Splits SS |

Scorched Pieces SP Scorched Pieces SP |

Scorched Small Pieces SSP Scorched Small Pieces SSP |

|

CASHEW KERNELS – DESSERT PIECES

|

Scorched Pieces Seconds (SPS) |

Dessert Pieces DP |

For wholes

Definition of wholes:

- In AFI standards, wholes are defined as kernels having the characteristic shape of the cashew kernels and not more than 1/8th of the kernel has been broken off.

- In UNECE standards, whole kernels are defined as those with the characteristic shape and the presence of a small hole at the proximal end of the kernel or a central split or crack is not considered as a defect. A kernel with no more than 1/8th of the kernel broken off is also considered as whole.

- In CEPC and BIS standards, there is no such specific mentioning about the allowable limit for broken off part of the kernel.

Classification of whole kernels:

In AFI standards, the whole kernels are classified as First quality fancy, Second quality scorched/color variation, Third quality scorched/color variation, Fourth quality and Dessert based on colour and appearance.

In AFI standards, the whole kernels are classified as First quality fancy, Second quality scorched/color variation, Third quality scorched/color variation, Fourth quality and Dessert based on colour and appearance.- In UNECE standards, the kernels are classified as “Extra” class, Class I and Class II based on the colour, appearance, uniformity, etc.

- In CEPC standards, wholes are further classified as “White wholes” (W), “Scorched wholes” (SW) and “Dessert wholes” (DW) based on colour and appearance.

- In Brazilian standards, the wholes are designated as “wholes’ (W1), ‘scorched wholes” (W2), “second scorched wholes” (W3) and “Fourth quality wholes” (W4).

Provisions concerning size specifications:

- AFI: compulsory for first quality fancy and optional for other whole grades.

- UNECE: compulsory for Extra class and optional for Class I and Class II.

- In CEPC standards, Sizing is given for “white wholes” and “scorched wholes” and not for “Dessert wholes”. Brazilian standards: It seems that sizing exists for “wholes” and “Scorched wholes” but not for “second scorched wholes” and “Fourth quality wholes”.

| Sizes and Counts Per Pound | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

The size specifications for the most liquid grades namely 240, 320 and 450 remain the same across the standards.

Tolerance limits:

- In AFI standards specifications are given clearly for serious damage and defects for all the whole grade classifications whereas in UNECE standards, the allowable tolerance limits are given specifically for Extra class, Class I and Class II.

- In CEPC standards, specifications are given for allowable percentage of brokens and maximum moisture content and it is 5% for both.

- BIS standards brokens and next lower grade should not exceed by 5 % of the weight of the packing. The other requirements such as free from moulds, insects, extraneous matters etc are just mentioned and no specific tolerable limits are given. But it has been specified that the kernels should be completely free from rancidity.

Size tolerances:

- AFI standards: Next lower grade (NLG) should not exceed by 10% of the weight of the wholes.

- UNECE standards: NLG should not exceed by 5% for “Extra” class and 7.5% for Class I.

- CEPC standards: The allowable limit for next lower grade is 5% for white wholes and 7.5% for Scorched and Dessert wholes.

- BIS standards: The allowable limit for next lower grade for wholes is 5%.

For Butts

Definition: In AFI standards, the butts are defined as the kernels that are less than 7/8 but not less than 3/8 of a whole kernel and the cotyledons are still naturally attached. The splits are defined as the kernel one half of which has been split length wise provided not more than 1/8 of this cotyledon has been broken off.

Definition: In AFI standards, the butts are defined as the kernels that are less than 7/8 but not less than 3/8 of a whole kernel and the cotyledons are still naturally attached. The splits are defined as the kernel one half of which has been split length wise provided not more than 1/8 of this cotyledon has been broken off.

In UNECE standards, brokens are defined as those kernels where 1/8 or more of the original kernel is broken off. Brokens are further classified into butts, splits and pieces.

- Butts are defined as the kernels of not less than 3/8 of a whole kernel which have been broken cross wise but the cotyledons are still naturally attached.

- Splits are the kernels that are split length wise.

- Pieces are the kernels that are broken more than two pieces.

(The specification for buts in AFI and UNECE standards are same.)

In BIS and CEPC standards, the kernels that are broken cross wise and naturally attached are described as butts and kernels that are split naturally lengthwise are described as splits. No specific size as part of the wholes is given.

Classification of pieces:

- In AFI standards, the pieces are classified as “large pieces”, “small pieces”, “chips or small pieces”, “grains, granules or baby bits”, “fine grains”, “fines”, and “mixed pieces” based on the size.

- In UNECE standards, the pieces are classified as “Large pieces”, “Small pieces”, “Very small pieces”, “Baby bits or granule” based on the size.

- In Brazilian standards, the pieces are broadly classified as “large pieces”, “small pieces”, “small Brazilian pieces” and “Brazilian granules” based on size.

- In CEPC and BIS standards, the pieces are broadly classified as “white pieces”, “scorched pieces” and “Dessert pieces” based mainly on the colour and appearance.

- In AFI, CEPC, BIS and Brazilian standards, within the broad classification of pieces there are various grade designations.

Size Descriptions:

| S.No | Standards | Major classification | Grade Designations | Sieve Size in mm | |

| Passing through | Retained on | ||||

| 1 | AFI | Large pieces | LWP, SP, SPS, DP, P1, P2, P3 | 8.0 | 4.75 |

| Small pieces | SWP, SSP, DSP, SP1, SP2, SP3 | 4.75 | 2.80 | ||

| Chips or special small pieces | CHIPS or SSP1, SSP2, SSP3 | 2.80 | 2.36 | ||

| Grains, granules or baby bits | BB or G1, G2, G3 | 2.36 | 1.70 | ||

| Fine grains | X | 1.70 | 1.18 | ||

| Fines | FE | 1.18 | N/A | ||

| Mixed pieces | P1M, P2M, P3M | To be determined by the buyer and seller | |||

| 2 | UNECE | Large pieces | – | 4.75 | |

| Small pieces | – | 4.75 | 2.80 | ||

| Very small pieces | – | 2.80 | 2.36 | ||

| Baby bits or granules | – | 2.80 | 1.70 | ||

| 3 | Brazilian | Large pieces | Large white pieces (P1), Scorched pieces (P2), Special scorched pieces (P3) | – | 4.75 |

| Small pieces | Small white pieces (SP1), Scorched small pieces (SP2), SP3 | – | 2.80 | ||

| Small Brazilian pieces | SSP1, SSP2, SSP3 | – | 2.36 | ||

| Brazilian Granules | G1, G2, G3 | – | 1.70 | ||

| X1, X2, X3, | – | 1.19 | |||

| 4 | BIS* | LWP, SP, SPS, DP | – | 4.75 | |

| SWP, SSP, DSP | – | 2.80 | |||

| BB | 1.70 | ||||

| 5 | CEPC* | LWP, SP, SPS , DP | – | 4.75 | |

| SWP, SSP | – | 2.80 | |||

| BB | – | 1.70 | |||

Size tolerances in various standards for brokens and pieces:

AFI standards:

- For Butts and splits: NLG (Next Lower Grade) should not exceed by 10% by weight.

- For Pieces: NLG should not exceed by 5% by weight.

UNECE standards:

- For butts and splits: NLG should not exceed 5% by weight for all the three classes namely, “Extra”, “Class I” and “Class II”.

- For pieces: NLG should not exceed 5% by weight for “Extra” class and 7% by weight for the other two classes

CEPC standards:

- For butts and splits, the grades, SSP, LWP, & SWP: NLG should not exceed by 5% by weight.

- For SB, SS, SP, SPS, DP: NLG should not exceed 7.5% by weight.

- For Baby bits: NLG should not exceed by 1% by weight.

BIS standards:

- For white pieces and scorched pieces: NLG should not exceed 5% by weight.

- For dessert pieces: NLG should not exceed 10% by weight.

The NLG limit specified in CEPC and UNECE standards seem to be same more or less.

Packing and marking:

The general particulars to be marked as specified in the standards are:

- Name of the product and trade name or brand name

- Name and address of the producer or packer

- Grade

- Net weight

- Country of origin

- Buyer’s name or marks

- Destination

- Other marks agreed to by buyer and seller.

The specifications regarding the particulars to be marked remain almost the same for the standards except that AFI has specified that country of origin is to be given and BIS has specified that name of the country where packed is to be given.

UNECE standards has specified that the marking for small retail packs should be made such that the letters are grouped on the same side, legibly and indelibly. Variety name or commercial type is also to be mentioned along with the country of origin. The optional specifications are crop year and the district or regional or local place name where the packed cashews are grown.

In CEPC standards, specifications regarding marking are not given.

Packing:

In CEPC standards, specifications are given for packing and standard weight, and shipping.

UNECE standards has specified that the use of materials like paper or stamps bearing trade specifications is allowed only if the printing or labeling has been done with non toxic ink or glue. Also the use of lead solder is not permitted. However, the exact size of boxes is not specified.

Practices in cashew trade:

Currently, most of the Indian traders use standards as recommended by CEPC, while some of them also follow AFI standards.

From: http://www.cashewinfo.com & http://www.cashewindia.org

White Wholes – 180

White Wholes – 180 White Wholes – 500

White Wholes – 500

Scorched Wholes Seconds

Scorched Wholes Seconds Dessert Wholes DW

Dessert Wholes DW Butts B

Butts B Scorched Butts SB

Scorched Butts SB